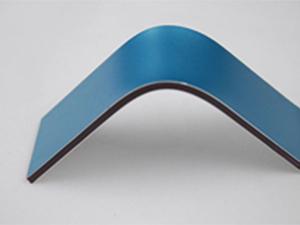

PVDF Coating Aluminum Composite Panel

PVDF coating aluminum composite panel consists of one polyethylene inner core which is sandwiched between two layers of aluminum. It is produced by continuous extrusion process. The panel is coated with PVDF Kynar500 fluorocarbon coating, which makes it more durable. It can be used to decorate the walls to make them quite beautiful.

Application:

Office buildings, shopping centers, industrial buildings, airports, hotels, bus centers, hospitals, schools, supermarkets, residential buildings.

-

Office buildings

Office buildings -

Bus center

Bus center -

Industrial buildings

Industrial buildings -

Residential

Residential

Raw materials:

Base material:High strength aluminum alloy panel

PE core material:Nontoxic low density polyethylene

Surface coating:PVDF Kynar500 coating

Backing coating:Primer coating

Features:

Shock resistance;

It's hard to peel from the wall;

High weather resistance;

Light in weight and easy to process;

Excellent fire resistance;

Coating uniformity;

Various colors to choose from;

Easy maintenance.

Product Specification:

Aluminum alloy: AA1100 series, AA3003 series, AA5005 series

Aluminum skin: 0.25mm, 0.30mm, 0.40mm, 0.45mm, 0.50mm

Thickness: 4mm, 5mm, 6mm

Width: 1220mm, 1250mm, 1500mm,1575mm,2000mm

Length: up to 6000mm

Color: 30 kinds. Special color available upon request

Special size on request.

Warranty: 20 years for PVDF KYNAR 500 coating

| Paint thickness | 25-28 micron |

| Paint type | KYNAR 500 PVDF coating |

| Warranty | 15-20 years |

| Fire resistance | B-s1-d0 according to EN13501 |